23

Feb

| Grain size | Cutting edge accuracy | Grain size | Application |

| A (rough) | 0.05mm | 230/270#~320/400# | Rough grinding |

| B (medium) | 0.02mm | M20~M40 | Medium grinding |

| C (finish) | 0.005mm | M5~M10 | Finish grinding |

Table1 Classified by cutting edge accuracy and usage

| Serial number | Degree of failure | Grain size | Remarks |

| A (rough) | Broken cutting edge 0.5mm | 230/270#~320/400# | Or electroprocessing |

| B (medium) | Cutting edge burst 0.3mm | M20~M40 | |

| C (finish) | Cutting edge wear 0.1mm | M5~M10 |

Table 2 Classification by the degree of cutting tools failure

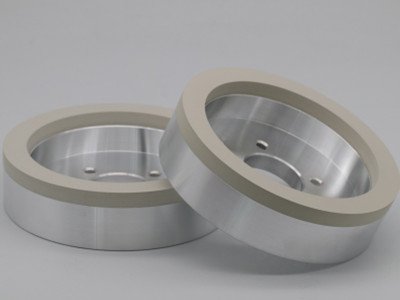

Rough machining does not require high cutting edge, and electrical machining or grinding can be selected. The electrical processing efficiency is high, and it is suitable for processing complex tools, such as drill bits for printed circuit boards, forming milling cutters for cutting laminate flooring, etc. Coarse-grained grinding wheel can be selected for grinding, with large contact area and high grinding force (300~400N) during sharpening, which can quickly remove excess machining allowance.