10

Jan

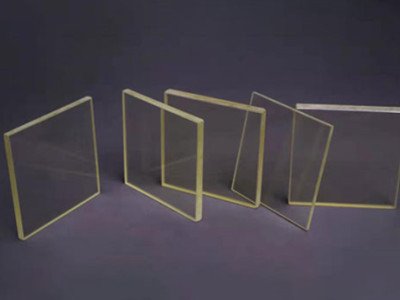

The customer is a company that mainly produces and sells special glass. Its products include the manufacture, processing and sales of radiation-proof glass, optical glass and glass lenses. Its customer base includes the medical device industry, and its specific application is the processing of ZF2 glass. This glass is widely used in the field of medical devices, and has extremely high requirements for processing accuracy and efficiency.

The life of the grinding wheel used by the client previously failed to meet production needs, resulting in high replacement frequency and increased downtime, which affected production efficiency and cost control. In order to optimize the process, the customer put forward the technical requirements of rough grinding and thinning grinding wheels

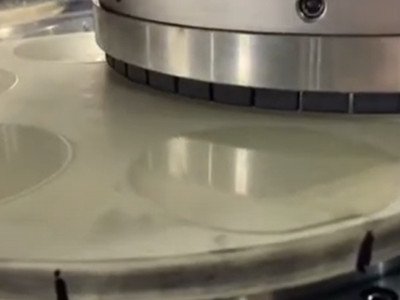

Grinding wheel specifications: D455-T34-H45.2, particle size 400#, metal bond diamond thinning grinding wheel.

Glass size: 800*800 for conventional processing, up to 1200*2400.

Life requirement: The service life of the grinding wheel must reach 1 month (previous products did not meet the standard).

Required products: The first batch of orders is 3 thinning grinding wheels, and subsequent requirements include double-end grinding discs and polishing pads to replace traditional cast iron discs.

To meet customer needs, we designed and produced a high-performance diamond grinding wheel specifically for the rough grinding and thinning process of ZF2 glass. The technical highlights are as follows:

1. Optimized abrasive layer design: The abrasive layer thickness is adjusted to 30 to ensure a significant increase in grinding life while maintaining processing accuracy and efficiency.

2. Improved metal binder: In response to the fracture problem reported by customers, the binder formula uses high-strength modified materials to ensure that the binder thickness exceeds 15 and still has sufficient toughness and durability.

3. Full process support: Provide a full range of solutions for subsequent double-end grinding discs and polishing pads, replace traditional cast iron discs, and improve production efficiency.

At present, the customer has received the first batch of 3 back thinning grinding wheels and is undergoing experimental testing. Preliminary feedback shows that the grinding wheel has excellent processing performance, and the grinding efficiency and life are better than the previously used products, which has achieved the customer’s expected goals.