25

Mar

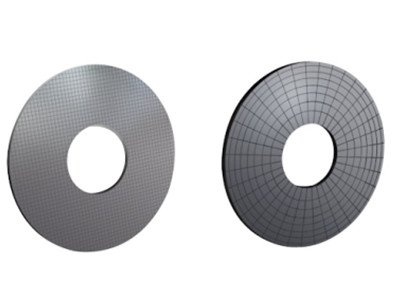

In modern manufacturing, the demand for precision machining and efficient production is growing. Traditional cast iron discs have gradually exposed problems such as low efficiency, unstable machining quality and high replacement costs in some applications. In contrast, superhard grinding discs (such as ceramic diamond grinding discs and ceramic CBN grinding discs) are becoming the mainstream trend to replace cast iron discs with higher machining efficiency, longer service life and better machining quality. This article will explore the necessity of superhard grinding discs to replace cast iron discs and the advantages they bring.

Although cast iron discs are widely used in grinding, their performance has the following obvious defects when facing high-hardness materials (such as alumina ceramics, high-speed steel, etc.):

Low machining efficiency: The grinding speed of cast iron discs is slow, which is difficult to meet the needs of efficient production.

Unstable surface quality: Rough surface, edge collapse or cracks are prone to occur during the grinding process, affecting the quality of the final product.

Fast Disc wear: Hard materials will accelerate the wear of cast iron discs, resulting in frequent replacement and increased production costs.

Serious environmental pollution: Traditional cast iron discs need to be used with grinding fluid, which can easily cause a dirty working environment and increase the cost of waste liquid treatment.

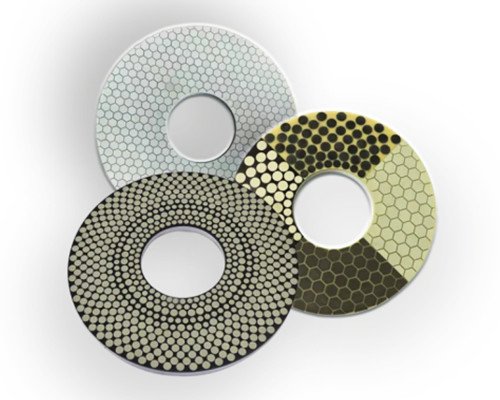

Superabrasives grinding discs (ceramic diamond grinding discs, ceramic CBN grinding discs) have obvious advantages in grinding high-hardness materials, which are mainly reflected in the following aspects:

(1) Significant improvement in processing efficiency

In the processing of alumina ceramic washers, the grinding speed of ceramic diamond grinding discs is increased by about 35%, which significantly shortens the production cycle.

The grinding speed of ceramic CBN grinding discs in the processing of high-speed steel parts is increased by 50%, which greatly improves production efficiency.

(2) Significant improvement in processing quality

The grinding disc has excellent cutting ability, which can ensure high surface finish and stable dimensional accuracy of the workpiece.

Compared with cast iron discs, ceramic diamond grinding discs have fewer edge collapse and crack problems when processing alumina ceramic washers, and the surface quality is significantly improved.

Ceramic CBN grinding discs can effectively reduce the problem of burning on the surface of high-speed steel parts and improve the product qualification rate.

(3) Longer service life and lower costs

The service life of ceramic CBN grinding discs is five times that of traditional cast iron discs, reducing the frequency of replacement.

Due to less grinding disc replacement and equipment downtime, ceramic diamond grinding discs and ceramic CBN grinding discs reduce overall production costs by 25%-30% respectively.

(4) Improved processing environment

Traditional cast iron discs rely on diamond grinding fluid, which leads to a dirty environment and high waste liquid treatment costs.

After using super-hard grinding discs, the processing process is cleaner, wastewater collection is more convenient, and the overall working environment is improved.

As the manufacturing industry develops towards high precision, high efficiency and green environmental protection, the application of super-hard grinding discs will be further expanded. In particular, replacing cast iron discs has become an inevitable trend in the following fields:

Precision ceramic processing: such as high-hardness ceramic parts in the electronics industry and medical devices.

High-end tool and mold manufacturing: such as grinding processing of high-speed steel and carbide tools.

Aerospace and automotive manufacturing: The demand for high-precision and high-wear-resistant parts is constantly increasing.

If you are looking for a more efficient, stable and environmentally friendly grinding solution, it is time to consider upgrading to a super-hard grinding disc! Contact us to get the grinding solution that best suits your needs and take your processing efficiency and product quality to a new level!