15

Sep

In the field of mechanical processing, cutting tools are the “sharp instruments” directly involved in cutting operations. However, as time passes and cutting proceeds, these tools will gradually experience wear. This not only affects processing efficiency but may also compromise processing quality. Today, we will uncover the truth behind tool wear, exploring its underlying causes, impacts, and corresponding countermeasures.

Tool wear refers to the phenomenon where the geometric shape and dimensions of a cutting tool change due to physical and chemical effects during its use. The main causes of tool wear include:

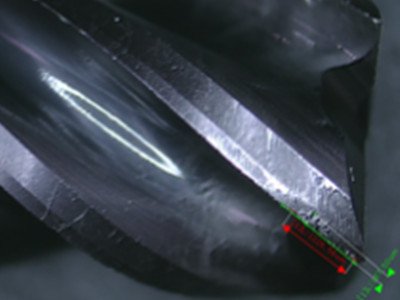

Mechanical wear: During the cutting process, friction between the tool and the workpiece material causes the material on the tool surface to gradually peel off.

Thermal wear: Heat generated during cutting softens the tool material, further intensifying wear.

Chemical wear: Chemical substances in the cutting fluid react with the tool material, leading to corrosion on the tool surface.

Impact and vibration: Impacts and vibrations during the machining process can also cause fatigue in the tool material, thereby accelerating wear.

Tool wear has direct and far-reaching impacts on the machining process:

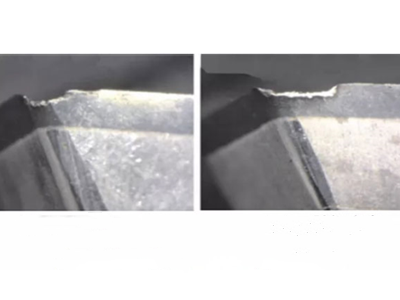

Reduced machining accuracy: Tool wear blunts the cutting edge, which impairs the surface roughness and dimensional accuracy of the machined part.

Decreased cutting efficiency: Worn tools require greater cutting force, thereby lowering cutting efficiency and extending machining time.

Shorter tool life: Continuous wear shortens the service life of tools, increasing the frequency of tool replacement and associated costs.

Higher machining costs: The reduced efficiency and tool replacements caused by wear lead to an increase in overall machining costs.

Strategies to Address Tool Wear

To mitigate the impacts of tool wear, the following strategies can be adopted:

Selecting appropriate tool materials: Based on the workpiece material and process requirements, choose tool materials with better wear resistance.

Optimizing cutting parameters: Reasonably set the cutting speed, feed rate, and cutting depth to reduce wear during the cutting process.

Using suitable cutting fluid: Selecting appropriate cutting fluid can lower the cutting temperature and reduce chemical wear.

Regular tool regrinding and replacement: Regularly inspect the wear condition of tools, and promptly regrind or replace them to maintain the cutting performance of the tools.

Moresuperhard offers a wide range of specialized grinding wheels for tool regrinding, tailored to different tool materials and machining requirements:

Vitrified Diamond Grinding Wheels: Ideal for regrinding PCD, PCBN, and ceramic tools. They deliver sharp cutting edges, high grinding efficiency, and excellent edge integrity.

Resin Bond Diamond Grinding Wheels: Best suited for carbide tool regrinding. They feature superior self-sharpening ability and provide excellent surface finish.

Hybrid Bond Grinding Wheels: Combine the advantages of vitrified and resin bonds, ensuring high-efficiency regrinding for complex tool geometries.

By using Moresuperhard’s high-performance regrinding wheels, customers can not only maintain the sharpness and cutting performance of their tools but also effectively reduce production costs and maximize tool life.

Adopting advanced coating technologies: Applying wear-resistant coatings (such as TiN and TiAlN) on the tool surface can significantly improve the tool’s wear resistance and service life.