04

Sep

Customer Requirement

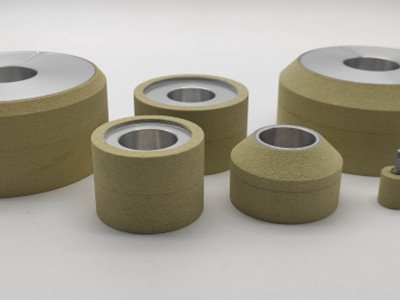

A customer recently ordered a batch of vitrified diamond grinding wheels with the specification 100D-45T-9.79X-45V-12h-30H SD120, used for tungsten carbide grinding. To meet different tool angles, the customer requested several wheels of the same grit size (SD120) but with different geometries.

Manufacturing Background

Vitrified diamond grinding wheels are widely applied in carbide machining due to their high precision retention, excellent heat dissipation, and long service life. However, when it comes to larger thickness, there are specific technical challenges:

The vitrified bond is harder and more brittle compared to resin, making single pressing of very thick wheels prone to internal stress and uneven structure;

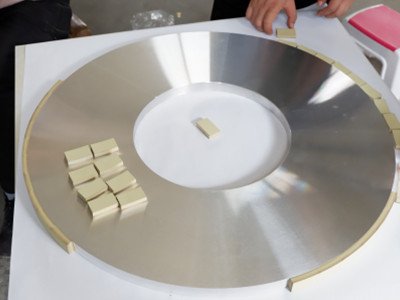

To ensure structural stability and grinding accuracy, the production process often uses two-piece pressing and joining to achieve the required thickness.

Customer Question

After receiving the wheels, the customer raised a rather naïve question:

“Since the wheel is made of two pieces, can it be taken apart and used separately?”

Professional Explanation

The answer is definitely no. Once manufactured, the two pieces are firmly bonded and become a single integrated structure:

There are no tools designed to “split” vitrified diamond wheels;

Any attempt to forcefully break them apart would destroy the bond, cause diamond layer peeling, and make the wheel unusable;

More importantly, the wheel would lose its concentricity and balance, which are critical for precision grinding.

In short, a vitrified diamond grinding wheel is not designed to be disassembled. If different thicknesses or structures are required, the correct approach is to customize the wheel during production rather than modifying it afterward.

Key Takeaways

Design Rationally – For thick vitrified diamond wheels, two-piece pressing is a reliable method, but the final product must be designed for end use.

Communicate Clearly – Manufacturers should explain production limits and design details to customers in advance, to avoid misunderstandings.

Precision Matters – Once the wheel is produced, its accuracy and structure are fixed. Any external force will compromise performance and safety.

Conclusion

This case highlights that while vitrified diamond grinding wheels deliver excellent results in tungsten carbide machining, understanding the manufacturing process is essential. When in doubt, customers should consult the manufacturer directly rather than attempting modifications.

MoreSuperHard continues to provide professional grinding solutions for hard-to-machine materials, ensuring precision, efficiency, and safety for our customers worldwide.