10

Feb

As a special alloy with shape memory effect, superelasticity and biocompatibility, nitinol is widely used in high-end fields such as aerospace, medical devices and precision instruments. However, its machining is extremely challenging due to its high hardness, high toughness and low thermal conductivity, which easily cause springback, burn and tool sticking, putting strict requirements on grinding tools. Both diamond grinding wheels and CBN (cubic boron nitride) grinding wheels are superhard abrasive tools for difficult-to-machine materials, but their adaptability to nitinol machining varies significantly. This article comprehensively compares their performance, applicable scenarios and practical effects based on nitinol’s machining characteristics, to clarify the optimal selection scheme.

To select the right grinding wheel, it is crucial to clarify nitinol’s grinding pain points, which determine that the wheel must have four core properties: high hardness, high wear resistance, low chemical affinity and good thermal conductivity. The key difficulties are as follows:

1. Coexistence of High Hardness and High Toughness: With a hardness of HRC40-50 and excellent toughness, nitinol generates large cutting resistance during grinding. Ordinary abrasive wheels are prone to wear and passivation, failing to achieve efficient cutting.

2. Low Thermal Conductivity Leading to Burning: Its thermal conductivity is only 1/5-1/10 that of ordinary steel. Grinding heat is hard to dissipate quickly, accumulating on the workpiece surface and causing burn, oxidation, and damage to surface performance and shape memory effect.

3. Strong Chemical Activity Causing Tool Sticking: In high-temperature grinding environments, nitinol easily reacts with abrasives, leading to chip adhesion and pore blockage, which increases grinding resistance and worsens workpiece burn.

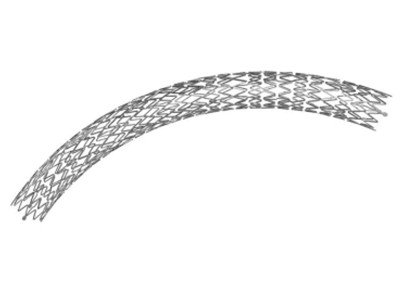

4. High Machining Precision Requirements: Nitinol is mainly used in precision parts (e.g., medical stents, aerospace seals), requiring strict surface roughness and dimensional accuracy. The grinding wheel must maintain long-term sharpness and shape stability to reduce dressing times.

Based on these difficulties, the grinding wheel for nitinol must solve four key problems: wear resistance, anti-sticking, heat dissipation and shape retention. The core performance differences between diamond and CBN wheels directly determine their adaptability.

Both diamond and CBN wheels have the advantages of superhard abrasives, but differ essentially in chemical composition, thermal stability and chemical affinity, resulting in distinct pros and cons in nitinol machining.

Diamond wheels, with Mohs hardness 10 (the hardest grinding tool), excel in grinding hard and brittle materials but have obvious limitations in processing tough materials like nitinol.

Minor Advantages: Their ultra-high hardness and sharpness enable fast material removal in the initial grinding stage, suitable for short-term rough grinding with small allowance and low surface quality requirements. High-quality diamond wheels can also achieve fine-grain grinding for low surface roughness, matching some precision needs if chip sticking is controlled.

Core Limitations (making them unsuitable for main processing):

1. Strong Chemical Affinity and Severe Tool Sticking: Composed of carbon, diamond easily undergoes diffusion reactions with nickel and titanium at high temperatures, causing abrasive passivation and blackening. Workpiece chips adhere to the wheel surface, blocking pores, reducing efficiency, and causing scratches and burns.

2. Insufficient Thermal Stability: Diamond graphitizes and loses hardness at around 600℃, which is often exceeded during nitinol grinding, leading to rapid wheel wear, failure and shortened service life.

3. Insufficient Toughness and Easy Chipping: Brittle diamond abrasives are prone to chipping under the impact load of grinding tough nitinol, failing to maintain long-term sharpness and requiring frequent dressing, which affects efficiency and precision consistency.

4. High Comprehensive Cost: High-quality diamond wheels are much more expensive than CBN ones. Their short service life and frequent dressing result in higher long-term unit processing costs, not suitable for mass production.

CBN wheels, with Mohs hardness 9 (second only to diamond), have better thermal stability, chemical inertness and toughness, making them the mainstream preferred tool for nitinol machining. Their advantages fully address nitinol’s grinding pain points, and limitations can be avoided by reasonable selection.

Core Advantages:

1. Strong Chemical Inertness, No Tool Sticking: CBN has no chemical react

ion with nickel and titanium, even at high temperatures, effectively avoiding chip adhesion and pore blockage. This ensures smooth grinding, reduces scratches and burns, and protects nitinol’s shape memory effect and biocompatibility—its key advantage over diamond wheels.

2. Excellent Thermal Stability: CBN can withstand 1250-1350℃, much higher than nitinol’s grinding temperature (usually below 800℃). It maintains hardness and sharpness long-term, with a grinding ratio of 3500-5500 (3-5 times that of diamond wheels).

3. Excellent Toughness and Chipping Resistance: Tougher than diamond, CBN abrasives resist impact load during grinding, not easy to chip. They maintain wheel shape stability, reduce dressing times, and ensure consistent precision in mass processing.

4. Good Thermal Conductivity, Reducing Burning: With thermal conductivity higher than ordinary abrasives and nitinol (1/2 that of diamond), CBN quickly dissipates grinding heat, avoiding heat accumulation, burn, oxidation and thermal deformation.

5. Wide Adaptability, Balancing Efficiency and Precision: CBN wheels with different binders fit the entire grinding process: resin-bonded wheels for fine grinding (good surface quality); ceramic-bonded wheels for rough grinding (porous, non-clogging); metal-bonded wheels for mass processing (high efficiency, good shape retention).

6. Better Comprehensive Economy: Though slightly more expensive than ordinary wheels, CBN’s long service life, low dressing frequency and high efficiency reduce long-term unit processing costs, suitable for industrial production.

Minor Limitations (avoidable by selection):

Slightly lower hardness than diamond leads to slower initial material removal when grinding extremely hard precipitated phases in nitinol, which can be compensated by selecting coarse-grain, high-concentration CBN wheels. Additionally, CBN decomposes in alkaline solution at 300℃, so oil-based coolant (not water-based) should be used, which is easy to implement via standardized processes.

Based on the above comparison and industry experience, the core selection conclusion is clear: Prioritize CBN wheels as the main tool; diamond wheels are only auxiliary in specific scenarios, not recommended as the main tool. Specific suggestions for practical production are as follows:

1. Rough Grinding (allowance removal, rapid forming, e.g., nitinol bar rough machining): Select ceramic-bonded CBN wheels (grain size 46#-80#, concentration 100%-120%). Ceramic binders are porous, non-clogging and heat-dissipating, avoiding high-temperature burning. High-concentration abrasives improve material removal rate, balancing efficiency and stability. Metal-bonded CBN wheels are also optional for high efficiency and shape retention.

2. Fine Grinding (surface quality and precision, e.g., medical stents, precision seals): Select resin-bonded CBN wheels (grain size 100#-200#, concentration 80%-100%). Resin’s elasticity reduces impact, avoids microcracks, and achieves low surface roughness (up to Ra0.02μm), matching diamond’s finish without tool sticking.

3. Mass Production (e.g., aerospace component batch processing): Select ceramic or metal-bonded CBN wheels with automatic grinding equipment. Their long service life and dressing cycle reduce downtime, improve efficiency and ensure precision consistency, with optimal economy.

Diamond wheels are only suitable for two special cases with specific processes:

1. Rapid removal of hard and brittle surface coatings (e.g., oxide, nitride) on nitinol: Use diamond wheels for short-term grinding, then switch to CBN wheels for main processing immediately after coating removal.

2. Ultra-high surface finish requirements (Ra≤0.01μm) with minimal allowance (≤0.05mm): Use fine-grain (above 200#) resin-bonded diamond wheels for final finishing, with special coolant to reduce tool sticking and burning.

Reasonable grinding processes are essential to avoid pain points and improve quality, regardless of wheel type:

1. Cooling Method: Use oil-based coolant (e.g., special grinding oil GF-2/GF-3) instead of water-based coolant (to prevent CBN decomposition and diamond tool sticking). Increase cooling flow to ensure uniform coverage and heat dissipation.

2. Grinding Parameters: Adopt “low rotation speed, small feed rate, multiple grinding” to reduce single-grinding heat and impact, avoiding workpiece burning and wheel chipping.

3. Wheel Dressing: Dress CBN wheels with diamond dressing pens and diamond wheels with special dressing rollers. Adjust dressing frequency based on batch size and wear to avoid using passivated wheels.