29

Nov

Wafer chamfering refers to the process of using a high-speed diamond grinding wheel to process the edge of a silicon wafer to form a bevel or rounded corner. The main purpose of silicon wafer chamfering is to reduce the sharpness of the edge of the silicon wafer. By chamfering the silicon wafer, the edge can be smoothed, the sharp edge area can be eliminated, the stress can be released, and the occurrence of edge cracking can be greatly reduced. Edge chamfering can also prevent possible damage and injury.

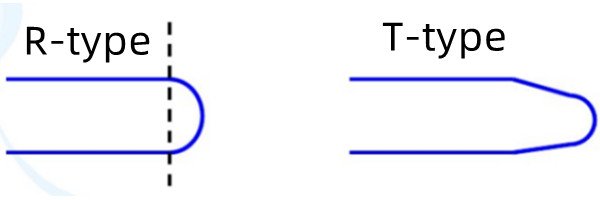

Depending on the needs, chamfers are divided into T-type chamfers (large chamfers) and R-type chamfers (small chamfers).

(1) Prevent wafer edge breakage. During the manufacturing and use of wafers, they are often hit by robots, etc., causing the wafer edge to break and form stress concentration areas. These stress concentration areas will cause the wafer to continuously release contaminated particles during use, thereby affecting the product yield.

(2) Prevent thermal stress concentration. When wafers are in use, they will undergo countless high-temperature processes, such as oxidation and diffusion. When the thermal stress generated in these processes exceeds the strength of the silicon lattice, dislocation and stacking fault defects will occur. Rounding the edge of the wafer can prevent such defects from occurring at the edge of the wafer.

(3) Increase the flatness of the epitaxial layer and photoresist layer at the edge of the wafer. In the epitaxial process, the growth rate of the sharp-angle area is higher than that of the flat surface. Therefore, wafers that are not rounded are prone to protrusions at the edge. Similarly, when applying photoresist using a spin coater, the photoresist solution will also accumulate at the edge of the wafer. These uneven edges will affect the accuracy of the mask focus.

Metal bond diamond edge grinding wheels are commonly used for chanfering wafers like silicon wafers,SiC wafers,GaAs,sapphire etc.

In order to minimize the roughness and ensure the processing efficiency, the chamfering grinding wheel with different abrasive grains from large to small is usually used to chamfer the silicon wafer multiple times to finally obtain a smooth surface. For example, first use 800# rough chamfering, then use 3000# grinding wheel for fine chamfering, and finally obtain a smooth surface. The average roughness Ra<0.04um.

R-type chamfer: R-type chamfer means that the contour formed after the wafer edge is chamfered is in the shape of an arc. This chamfering method can effectively reduce the stress concentration at the edge of the wafer and is suitable for most semiconductor processing processes. R-type chamfer is usually used for lightly doped wafers.

T-type chamfer: T-type chamfer means that the contour formed after the wafer edge is chamfered is in the shape of a right angle. This chamfering method may be more suitable than R-type chamfer in certain specific applications, such as when more precise control of the wafer edge contour is required. T-type chamfer accounts for a high proportion in heavily doped wafers.